Automation

UNISON™ Distributed Control Systems

We are in a very unique position in the cement industry. PSCL has been working with the cement industry for almost 30 years, and is truly trusted by our clients.

I see that trusted position is going to help drive process solutions and enable us to provide wall-to-wall automation services within our clients’ facilities.

VP · Automation

The depth of experience, and a vision for ever-evolving needs

History

Introduced by PSCL in 1985, the UNISON™ Distributed Control System (DCS) is implemented in the cement and oil & gas industries, and in a campus-wide HVAC. These installations still run today.

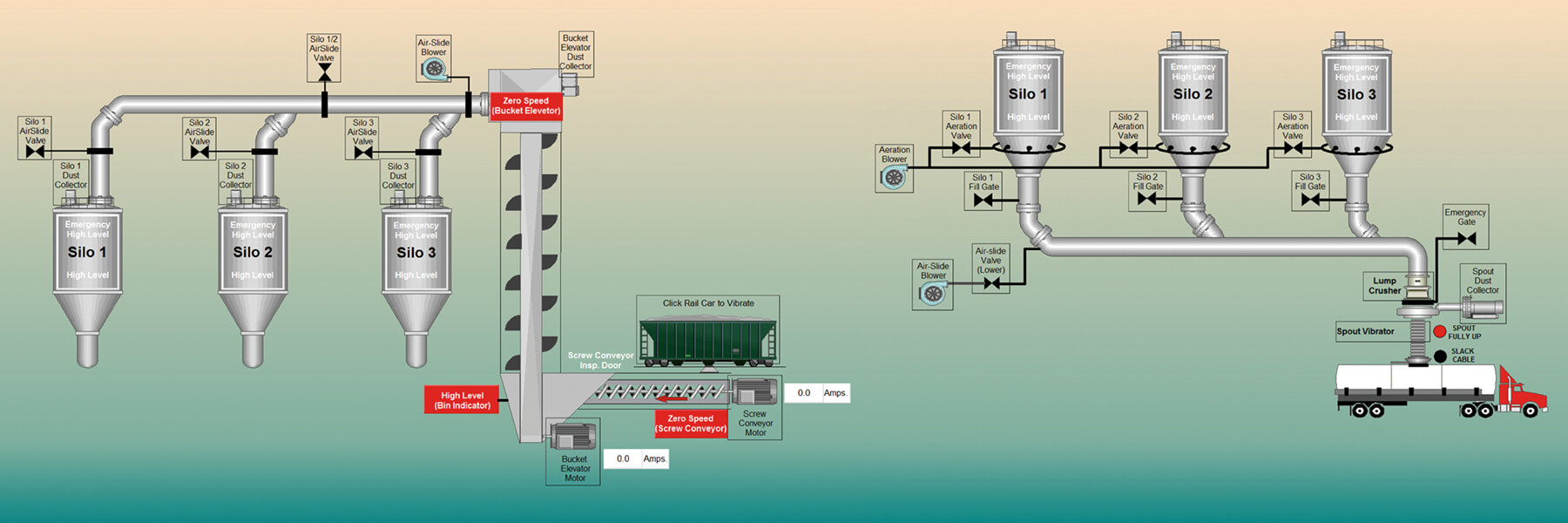

UNISON is a collection of integrated products providing a human and commercial interface to process control field hardware. The integrated network architecture of UNISON provides building blocks for cost-effective control solutions from small PLC-based systems with less than 200 monitored points, to large control systems with multiple, independent networks of hundreds of remote microprocessors and databases of 100,000 or more points. UNISON also incorporates a process historian essential to control and planning. Sites running UNISON can play back their HMI screens like video – with some able to scan through 20 years of data.

UNISON was part of the DCS revolution. We’ve all seen the grey beard get teary eyed talking about running the plant on a PDP-11. We were there, and we’ve stayed true to our roots.

UNISON

UNISON holds all the advantages of distributed control: reliability through distributing the control process, but solid integration of the plant level and historical data integration. Field I/O isn’t forever. Manufacturers have to keep up with changes in materials and technology. Changing your I/O should not mean re-automating your whole plant.

UNISON works with what you have, and what you have coming. Allen-Bradley, Siemens, Schneider. The UNISON PCM scans and manages a wide variety of standard I/O, letting you chose the right technology for each local control application. Interlock, alarming and group start routines are untied from vendor specific requirements. From RS-485 to IoT, upgrade your data acquisition without retraining your operators.

Automation Services by PSCL

Shouldn’t your solutions provider understand all of your challenges?

- ERP Integration

- Operations

- Automation

PSCL does. We know that automation is the foundation to all of our distribution and quality solutions. We offer automation services so that you have peace of mind and consistency in your business solutions from PSCL.

What We Offer

- End-to-end project management

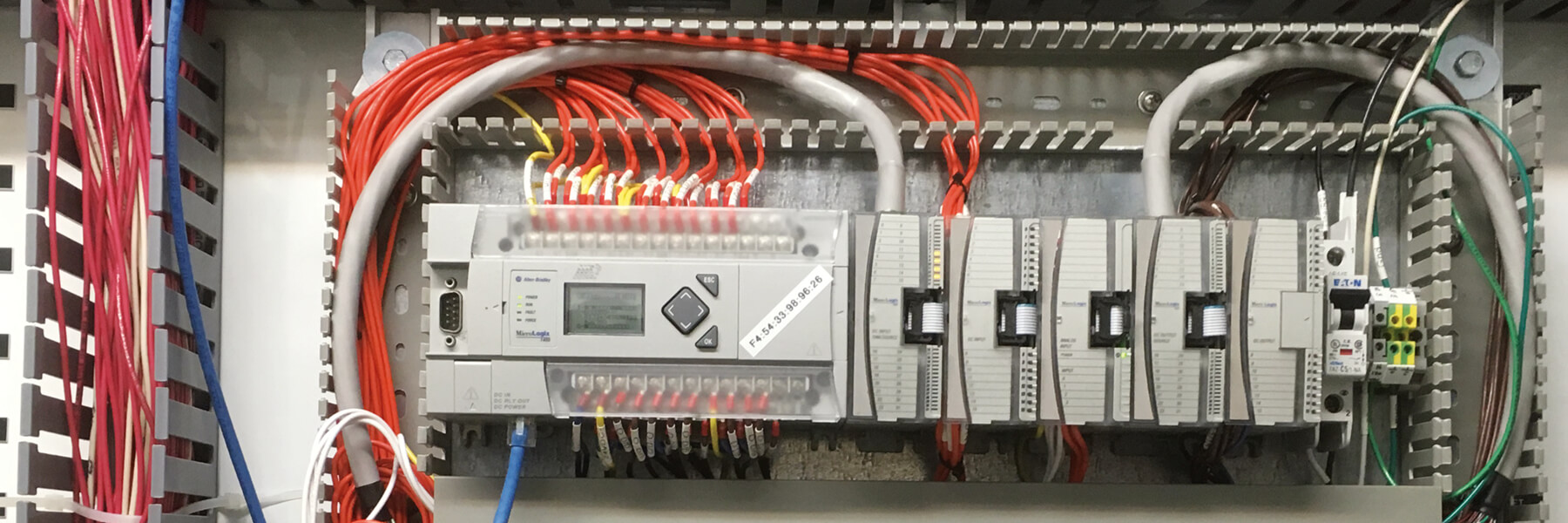

- PLC programming

- HMI development

- Terminal re-automation

- New terminal automation

How We Do It

Proven processes and project management expertise to:

- Identify requirements

- Solve issues

- Minimize cost

- We have hardware expertise

- We build PLC panels based on our field-proven kiosk technology

- Our people are unique in their cement industry exposure – we have decades of cement automation expertise to understand your challenges

- We maintain meticulous records of all of our installations, so our knowledge is never lost

Customer Support and Integration

Our team of experts work with you to customize, install, integrate, implement and maintain the necessary hardware and software.

With decades of experience, the Support & Integration team carry out on-site installation commissioning and provide full-time help desk support. We provide solutions which grow with your operations, proving their value year over year.